- Products

- News & Dates

- Service & Support

- About Dietrich's

-

Ossabois is a pioneer in the off-site construction of timber buildings and currently the French market leader in this sector. The company can prefabricate the customised modules for the designed structures in its three factories thanks to special construction processes on site in France.

These are then transported ready for assembly to the construction site. This method has the advantage of saving up to 70% of construction costs and cutting construction times by up to 60% compared to conventional construction methods.

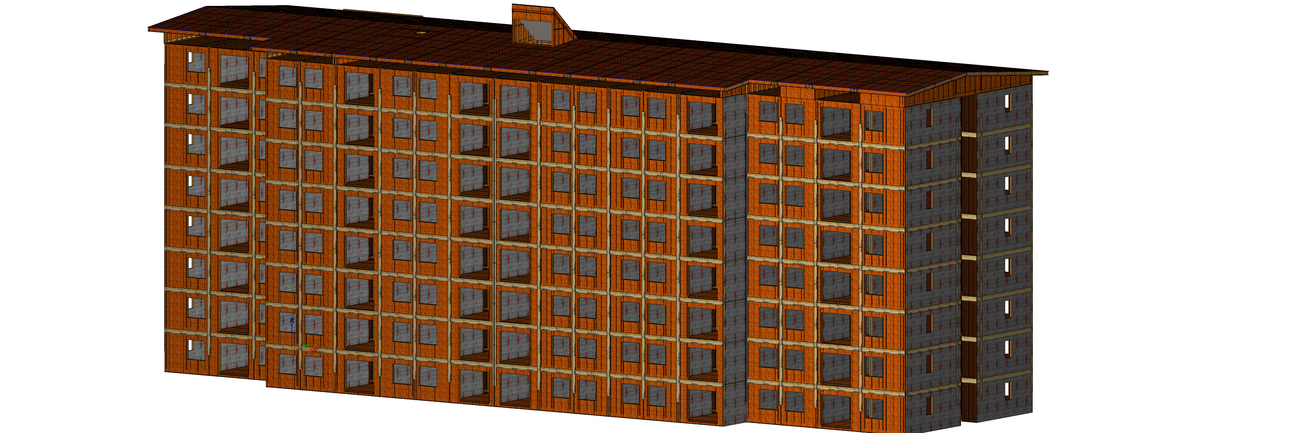

Ossabois has now completed the MMV Étoile des Sybelles residence in the heart of France's fourth largest ski resort in Le Corbier in Savoie, Europe's highest situated building complex, which was built using 100% modular timber construction. The 10,000 m² building designed by Hubert Architecture extends over 8 storeys and comprises a total of 310 timber modules.

Compared to a comparable conventional building, off-site production and the use of renewable materials saved around 30% of CO2 emissions and up to 40% of waste. The building will be used permanently for tourism over the next 30 years to fulfil the sustainable vision for the building.

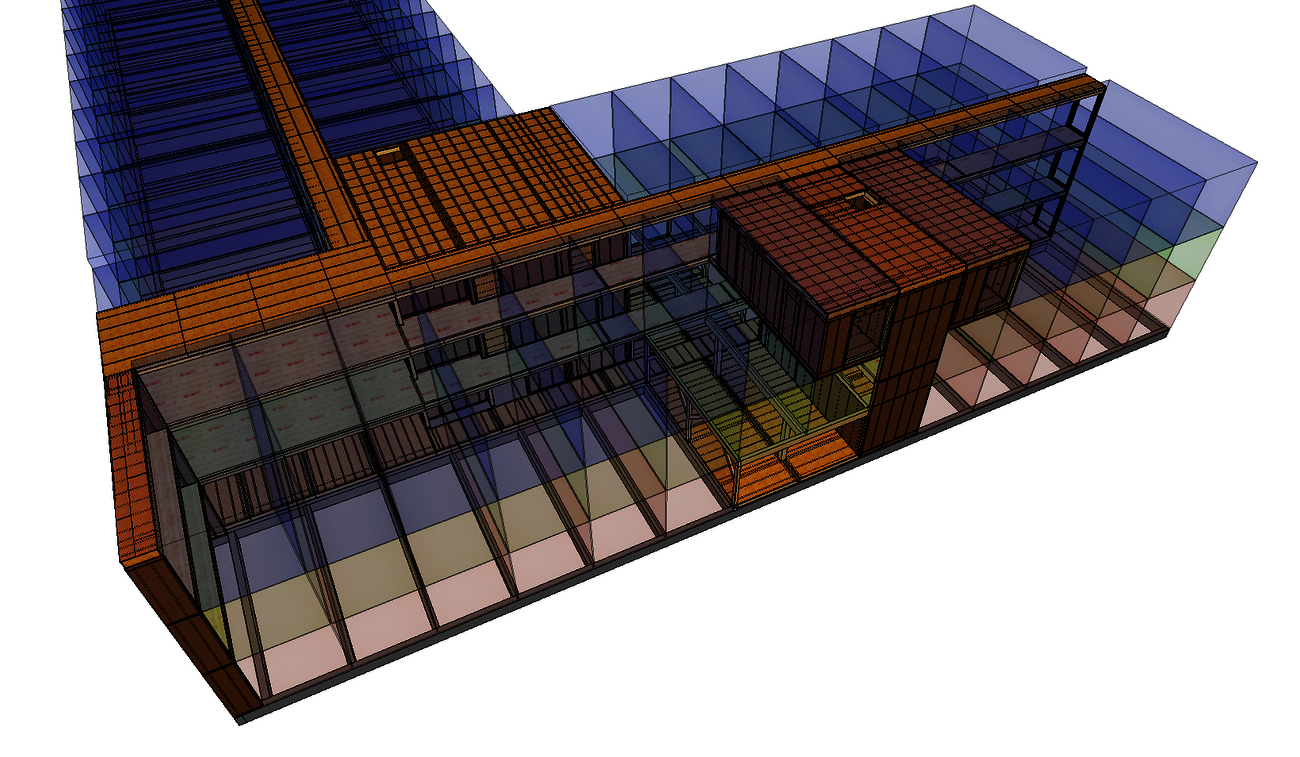

This large timber construction project was modelled entirely in 3D using Dietrich's digital tools. To maximise the efficiency of the planning and production of the 310 modules that make up the building, a total of three floor types and 7 flat types were identified. It was very easy to import the entire planning of the technical building equipmentinto the 3D model with the help of the IFC import. Further 3D modelling work was completed smoothly in OpenGL mode thanks to the D-CAM module.

Due to the unique structure of Dietrich's CAD files, it was possible to divide this large project into several smaller files to create logical work subsets. With the building library function in DIWALL, all parts of the building could be combined simultaneously in a single file. Dietrich's 3D modelling also facilitated the planning of the module assembly on the construction site. The DIWALL, JOINTING and ROOF modules were used to model the timber frame walls, ceilings and roofs.

They could also create all the files for transfer to the CNC machines. All 2D plans required for planning, production and assembly were created automatically using the PLAN-CAD module. In line with our claim to provide a largely integrated and seamless digital value creation process for timber construction, Dietrich's has supported this product from the planning stage right through to the construction site and provided the perfect solution for our requirements.