- Products

- News & Dates

- Service & Support

- About Dietrich's

-

The requirements of the future for modern, affordable, flexible and sustainable construction are obvious: We need serial construction with a high degree of customisation. Using environmentally friendly products made from renewable raw materials. It is important to have construction methods that meet neither yesterday's needs nor those of the day after tomorrow, but that can be flexibly adapted to the current requirements over the entire life cycle.

The company MOD21 has recognised this demand and is focusing entirely on modular timber construction. In 2021, MOD21 was founded as a modular construction start-up of the ERBUD Group, merged with GWI Bauunternehmung at the beginning of 2022 and reorganised itself under the new name MOD21. The Düsseldorf-based company with its production site in Ostaszewo near Toruń in Poland is a 100% subsidiary of the German-Polish ERBUD Group. With the new division, its modular timber construction, buildings will be constructed not only in conventional but also in modular or hybrid construction methods. MOD21 draws on many years of expertise in traditional modular construction.

The promotion of modular timber construction combines two key aspects and is an important response to the above requirements. Initially, this is due to the basic concept of modular construction. With modules, serial production is possible on the one hand and customised construction in a modular system on the other, i.e. tailored precisely to requirements. The positive side effects of series production: rapid availability plus an economical production and delivery process that boosts efficiency in the construction process. This applies to almost all dimensions, whether for single-storey nursery schools or multi-storey retirement homes, whether for hospitals or residential complexes.

Modular construction also impresses with its outstanding flexibility. As flexible components, the modules can be combined virtually at will: on one level or multiple floors. The planner has ample freedom to develop his ideas as he sees fit - and to create a construction method that precisely fulfils the needs of his clients. The second key aspect favouring modular timber construction is, of course, timber as a building material. This renewable raw material emits virtually no CO2 during the production process; on the contrary, it absorbs large quantities of CO2. Timber creates a healthier living environment and positive emotions, is environmentally friendly and can be perfectly integrated into a circular economy.

"Modular timber construction is demand-oriented because timber modules can be used at short notice. Their number and layout can adapt flexibly according to acute needs and is not subject to future projections. You can adjust the combination and number of modules upwards or downwards at any time. And if the need ceases to exist at some point, there will be no unused voids.

Modular timber construction can create high-quality and affordable architecture reliably and quickly, whether for single or multi-storey buildings, residential complexes, hotels, schools or hospitals. What's more, it is easy to combine timber modules with conventional construction to form "hybrid buildings", upgrading conventional buildings in the process.

This makes modular timber construction not only the solution to the need for readily available, flexible buildings, but also the answer to the challenges of ecological change - not least the transition from a resource-consuming construction industry with high energy requirements to an environmentally friendly circular economy. "If we start reforesting on a large scale and building with timber instead of concrete, then construction, as the biggest climate offender, will suddenly become the best friend of the climate," said Prof Schellnhuber in the weekly newspaper DIE ZEIT.

Dietrich's had recognised the potential of modular timber construction for some time and provides suitable solutions within its software. There are also significant enhancements planned for future versions with many additional options.

Today, a top player in timber module construction is already working with Dietrich's. The company MOD21 from Düsseldorf has equipped every single workstation with Dietrich's software and the co-operation is steadily growing.

Dietrich's is a partner who, like us, thinks in timber as well as having a high level of software expertise.

Theodor Kaczmarczyk, Managing Director MOD21

"We have a common understanding of what solutions are necessary and what we need to work effectively and economically. With Dietrich's software, we could significantly improve our processes and remain flexible."

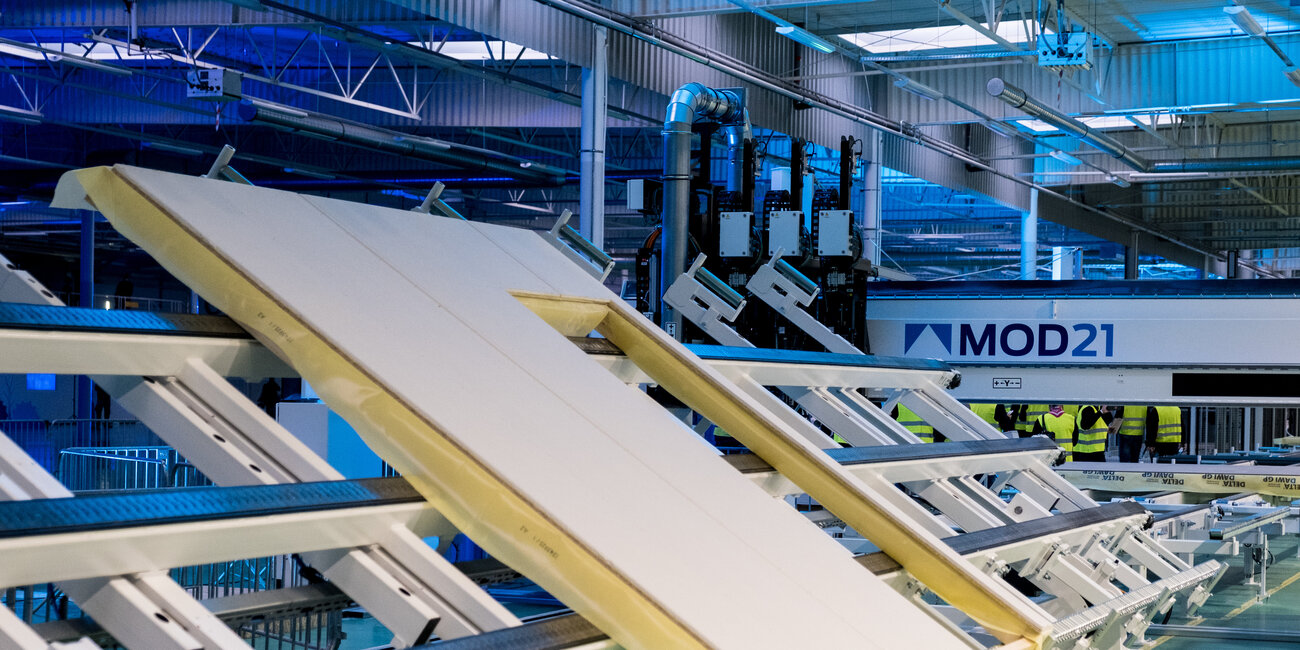

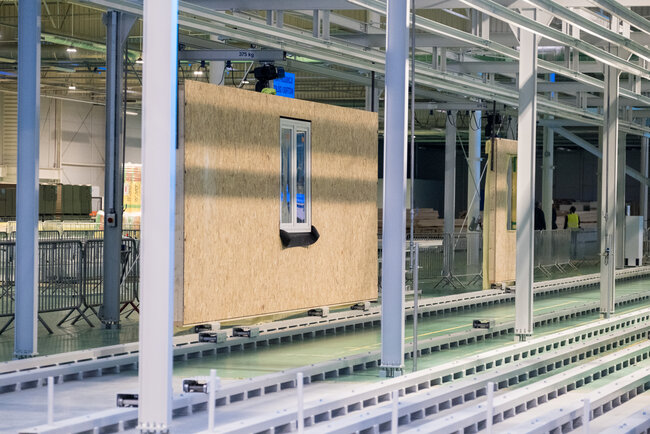

Dietrich's representatives were also present when MOD21 celebrated the opening of its new 21,000 m² production hall in Ostaszewo near Toruń, Poland, on 29 November 2022. In this hall, prefabricated elements for modular timber construction are produced under optimal conditions: a high-tech world of sustainability, timber and construction for the future. At full capacity, MOD21 can produce a module area of 375 m² per day in this new hall using timber from sustainable, FSC- or PEFC-certified forests.

Theodor Kaczmarczyk, Managing Director MOD21: "Our modular timber construction is the epitome of eco-friendly building solutions and one of the biggest breakthroughs in the industry. That's why MOD21 is designing the future of sustainable construction." The interest in the modules has already exceeded expectations. Dariusz Grzeszczak, founder of Erbud: "Today, I already know that these 21,000 m² of production hall space near Toruń are a drop in the ocean. It would be necessary to build three such halls at once."

The forecasts for the German market confirm that he is right. According to the Deutscher Holzwirtschaftsrat (DHWR - German Timber Industry Council), modular timber construction will account for half of the construction market in Germany by 2050. With the new MOD21 plant in Ostaszewo, Poland, and Dietrich's software, we have the right prerequisites.